Test method exposing waterlogged natural stones or building material to at least 10 freeze-thaw changes +20 °C/-20 °C. This serves for determination of changes, such as crack formation, weight loss, chipping and stability changes.

Premium Line P210 – P1700 with extension of the temperature range -30 °C and +80 °C as well as reinforced shelves

Premium-Linie >

Test method exposing concrete cubes, which have been soaked in de-icing agent, to 28 freeze-thaw changes +20 °C/-20 °C. This method serves for determination of the freeze and freeze-de-icing salt resistance weathering of concrete affected by freeze in combination with de-icing agents.

Premium Line P210 – P1700 with extension of the temperature range -30 °C and +80 °C as well as reinforced shelves

Premium-Linie >

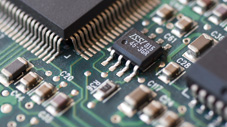

Test method for determination of the reliability of electrical components with connected supply voltage with cyclic temperature alternation. Normally, the temperature range to be tested corresponds to the temperatures occurring during the case of application.

Premium Line P210 – P1700 with extension of the temperature range -30 °C and +80 °C as well as reinforced shelves

Premium-Linie >

Test method, which is simulating an artificial ageing of an electrical component for early recognition of material or component weakness. Usually, the temperature ranges during the burn-in test are significantly higher than during the run-in test. If the component passes the burn-in test successfully, a high reliability can be expected.

Premium Line P210 – P1700 with extension of the temperature range -30 °C and +80 °C as well as reinforced shelves

Premium-Linie >